First Graphene Limited (ASX: FGR) has reported continued positive results in field trials of its graphene-enhanced cement, with a slab reaching over 200 days in operation at a wheel washing facility in South East England.

The enhanced concrete slab, incorporating First Graphene’s PureGRAPH, has maintained its strength and integrity, showing no defects, damage, or deterioration. The slab was prepared using a graphene-enhanced CEM II A/L concrete mixture produced by Breedon during site trials last year.

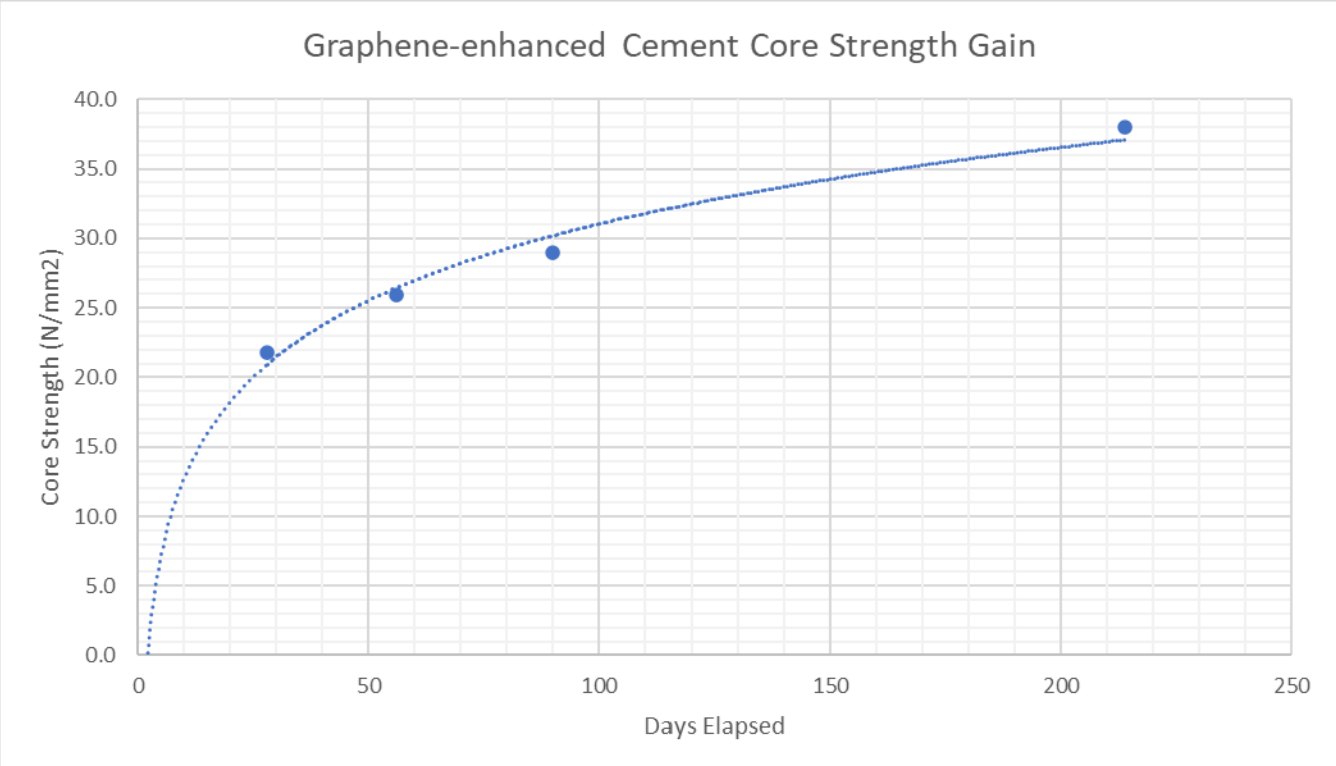

Increase in the core strength of graphene-enhanced cement used in concrete slab

The highway infrastructure project provides an ideal environment to test the strength and permeability of the graphene-enhanced concrete. Despite more than 150 heavy vehicle movements each day, as well as abrasion and wetting from washed wheels, the slab has shown resilience.

Core samples extracted from the enhanced concrete indicate good compressive strength performance, demonstrating the long-term strength of the material in a real-world aggressive environment.

The enhanced cement has also shown environmental benefits, with an immediate 15 per cent reduction in CO2 emissions during production due to its lower clinker factor.

The trial, conducted with partners including Breedon Group plc, Morgan Sindall Infrastructure, and the University of Manchester, was supported by the UK Government through Innovate UK.

First Graphene Managing Director and CEO Michael Bell stated: “These 200-day results represent a significant milestone in the trials of graphene-enhanced cement, with the integrity of the slab continuing to go from strength to strength.”

He highlighted the company’s contribution to developing cost-effective, environmentally friendly solutions for the construction industry.

The positive results have opened up opportunities for First Graphene to collaborate on future projects with partners in the UK construction industry, reinforcing the potential of graphene-enhanced cement as an emission-reducing and higher-performing solution for the cement and concrete industry.